Oklahoma Cannabis Compliance Guide: Preparing for HB 3361’s Pre-Packaging and Display Requirements

By Brad Holmes|January 29, 2025|7 mins read

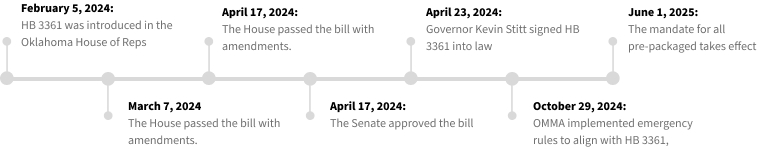

In April 2024, Oklahoma lawmakers passed House Bill 3361 (HB 3361), a piece of legislation that represents a major shift for the state’s medical marijuana industry. Designed to enhance consumer safety, ensure consistent product quality, and tighten regulatory compliance, this bill introduces significant changes that every cannabis business in Oklahoma must address.

Key aspects of HB 3361 include new requirements for pre-packaging medical marijuana products, stricter guidelines for packaging materials, increased administrative fines for non-compliance, and new rules around how products can be displayed and sampled in dispensaries.

With these changes set to take effect on June 1, 2025, businesses in the cannabis sector need to act now to adapt their operations, packaging, and employee training to avoid disruptions.

Understanding the bill and preparing for its implementation is critical to maintaining compliance, protecting your business, and continuing to serve Oklahoma’s growing medical marijuana market.

Table of Contents

Key Provisions of HB 3361

Mandatory Pre-Packaging:

Under HB 3361, all medical marijuana flower and flower-based products sold to dispensaries must be pre-packaged in parcels that do not exceed three ounces.

This shift aims to improve product safety, consistency, and transparency for consumers while reducing the risk of product tampering. Dispensaries will no longer be able to sell loose flower, requiring producers and processors to adopt compliant pre-packaging processes before delivering products to retail locations.

Packaging Material Specifications:

The bill allows for the use of non-opaque materials in cannabis packaging, provided all other state regulations are met.

This means businesses can use partially transparent materials, as long as they include the required product information, child-resistant features, and any warning labels. While this offers flexibility for branding and presentation, it places added responsibility on businesses to ensure their packaging is fully compliant.

Administrative Fines

To enforce the new regulations, HB 3361 introduces administrative fines for violations, such as failing to adhere to packaging requirements or mishandling pre-packaged products.

These fines emphasize the importance of compliance and serve as a deterrent against cutting corners. Businesses found in violation risk both financial penalties and reputational damage, making it critical to adopt thorough compliance practices.

Display and Sampling Restrictions

The legislation also regulates how cannabis products can be displayed and sampled in dispensaries. While visual display is allowed, certain forms of product handling, such as open containers for smelling or tasting samples, may be prohibited.

This measure aims to ensure consumer safety while maintaining the integrity of pre-packaged products. Dispensaries will need to implement alternative ways to inform customers about product attributes, such as detailed descriptions or sealed sample kits.

What is the Impact of HB 3361 on Cannabis Businesses in Oklahoma?

The implementation of HB 3361 will bring about significant operational changes for cannabis businesses in Oklahoma.

From adapting inventory systems to meet pre-packaging requirements to ensuring packaging materials comply with updated regulations, companies will need to navigate new challenges to stay compliant. Here are three things to keep in mind as you prepare for HB 3361.

Labor or Automation? Weighing the Best Approach for Packaging

With HB 3361 mandating pre-packaged flower, cultivators must decide how to manage this process efficiently: scale up labor or invest in automation?

A labor-intensive approach may be the most accessible short-term solution, allowing businesses to quickly add staff to manually weigh, portion, and seal their product. However, this method increases overhead costs and leaves room for inconsistencies in weight and packaging accuracy.

On the other hand, automation offers a long-term solution by streamlining the process with precision and speed, reducing labor costs over time and minimizing product waste. While automation requires upfront investment, solutions like automated weigh-and-fill machines or pre-roll automation from PreRoll can help cultivators efficiently meet the new packaging requirements while maintaining profitability. Ultimately, the right choice depends on a business’s scale, budget, and long-term growth strategy.

Compliance with Packaging Regulations

Adhering to the new packaging standards is not optional. Every package must meet Oklahoma’s guidelines, including pre-set weight limits, labeling, and child-resistant features.

Companies will need to audit their existing packaging to ensure compliance and may need to work with packaging suppliers who specialize in cannabis regulations.

Failure to comply with these requirements could result in not only fines but also the suspension of licenses, jeopardizing the company’s ability to operate in the state.

How to Stand Out in a Sea of Sealed Packaging

With budtenders no longer able to open jars and share strains with customers, packaging will play an even bigger role in how cultivators differentiate their products. In a competitive market, simply meeting compliance requirements won’t be enough—packaging needs to communicate strain details, product quality, and brand identity at a glance.

Clear, engaging designs with strain information, terpene profiles, and effect descriptions will be crucial for guiding consumer decisions. High-quality printing, custom embellishments, and standout branding can make a difference in whether your product gets noticed or blends into the background.

Packstudio offers customizable packaging solutions that help cultivators create visually appealing, compliant designs that grab attention on dispensary shelves and give customers confidence in their purchase.

Staff Training for Compliance and Product Presentation

For cultivators, the shift to pre-packaged products means training staff on new handling and compliance procedures before products even reach dispensaries. Employees involved in weighing, filling, and sealing must be well-versed in the latest packaging protocols to ensure every unit meets regulatory standards.

Proper training will also be essential for maintaining consistency in labeling, batch tracking, and quality control. Additionally, as dispensaries can no longer open jars for customer inspection, cultivators must prepare their sales and marketing teams to effectively communicate strain information, terpene profiles, and product quality through packaging and marketing materials.

Ensuring staff are knowledgeable about these changes will help streamline operations, prevent compliance issues, and support dispensary partners in selling pre-packaged products successfully.

Impact on Cultivators

For cultivators operating at scale, HB 3361 presents more than just a packaging challenge—it raises critical questions about efficiency and automation. With the new pre-packaging requirement, businesses handling high volumes of flower must decide how to package their product efficiently while keeping costs manageable. Do they invest in additional labor to manually weigh, portion, and seal each package? Or is automation the answer to streamlining operations and maintaining consistency?

This is where solutions like automated pre-roll and packaging systems come into play, helping cultivators meet demand without excessive overhead. Companies like PreRoll specialize in automation solutions that can help cultivators transition seamlessly to pre-packaged products, reducing bottlenecks and improving overall efficiency.

By integrating automation with compliant packaging solutions from Packstudio, cultivators can ensure they stay ahead of regulations while scaling their operations effectively.

How Packstudio Can Help

Preparing for HB 3361 doesn’t have to be overwhelming. By partnering with Packstudio, Oklahoma cannabis businesses gain access to industry-leading expertise and customized solutions that ensure compliance with all packaging and display requirements.

Custom Packaging Solutions

When it comes to meeting HB 3361’s new pre-packaging requirements, Mylar bags are the best solution for cultivators looking to maintain product freshness, comply with regulations, and create a standout brand presence. Mylar bags provide an airtight, light-resistant barrier that helps preserve potency and terpene profiles while keeping products compliant with child-resistant packaging laws.

They are also lightweight, cost-effective, and easily customizable—allowing cultivators to include strain details, branding, and regulatory information in a sleek, professional format. Whether packaging flower, pre-rolls, or other cannabis products, Mylar bags offer the ideal balance of protection, compliance, and marketability.

At Packstudio, we specialize in high-quality, custom-printed packaging solutions made in the USA and designed specifically for the cannabis industry. Our low minimum order quantities, quick-turn production, and fully customizable design options make it easy for cultivators to adapt to Oklahoma’s evolving regulations without sacrificing brand impact.

We offer Mylar bags in the state-mandated sizes for compliance, such as 4x5x2, 3.5×4.5×2, and 2.75 x 7.5 lay flat — as well as other sizes for all your cannabis packaging needs. Our variety of finishes and closure styles ensures you get a compliant, professional look that aligns with your brand identity.

Whether you need small-batch runs for limited strains or large-scale production for high-volume operations, Packstudio helps cultivators stay compliant, competitive, and ahead of the game in Oklahoma’s cannabis market.

How Businesses Can Leverage Packstudio

For a cannabis processor, shifting to pre-packaged products may feel daunting, but Packstudio can step in to streamline the transition.

With Packstudio, you can:

- create custom packaging designs with standardized sizes that meet the state’s three-ounce limit while reflecting the processor’s brand identity.

- comply with the new regulations while maintaining consistent branding across all products.

- create customizable, branded sample kits that feature sealed containers of flower strains, allowing customers to inspect products without violating the new rules.

Get an instant quote online or contact us to discuss your specific needs and ensure your packaging is compliant and visually appealing.

Partnering with Packstudio:

With Packstudio’s eco-friendly, high-quality packaging and regulatory support, businesses can transition smoothly to the new standards without disruption to operations.From design to delivery, Packstudio offers a one-stop solution that prioritizes compliance, branding, and operational efficiency.